The result

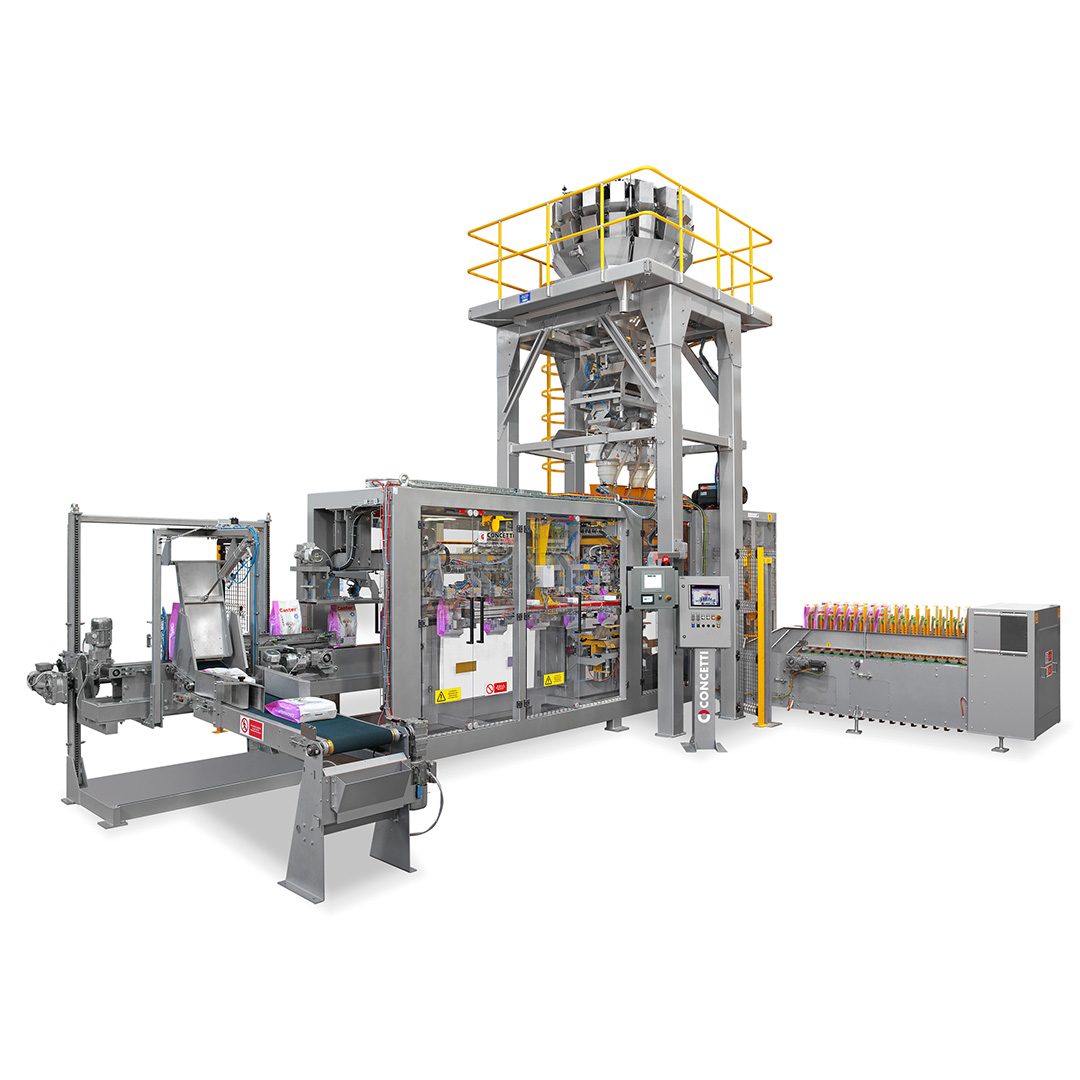

Flexible and automated packaging in a compact space

A future-proof packaging line that enables Aveno to meet the needs of today and tomorrow.

Customers in the food industry have diverse needs depending on their production processes. Whether it’s preparing mixtures, storing raw materials, or internally processing them, each customer works differently. Aveno’s new packaging line makes it easy to flexibly handle various packaging formats, allowing for seamless adaptation to these varying requirements.

Thanks to the smart design by Maxpac engineers, the available space is optimally utilized, while still maintaining enough room to ensure the ergonomics and safety of the workers.

Moreover, the automation of the packaging line has significantly reduced the need for manual operations. This not only reduced the workload for the operators but also significantly lowered the risk of errors.

With this solution, Maxpac delivers a future-ready packaging line that is prepared for growth and diversification. The collaboration between Aveno and Maxpac is an excellent example of custom solutions that optimize production processes to stay competitive in an ever-changing food market. And we’re far from finished! The collaboration continues to evolve, with even more innovative solutions on the horizon. For example, we are currently working on the integration of a new palletizing machine, a smart combination of second-hand and new technologies, to further improve efficiency. More to come!